24 Jun how to obtain an always efficient paint gun

Davide Pironi, Sales and Business Manager of spraycolor® advises us on maintaining the efficiency of spray guns for industrial painting.

Here is how to keep the painting quality high, saving on both wear and consumption, for the benefit of your company and the environment.

What must the worker take into consideration?

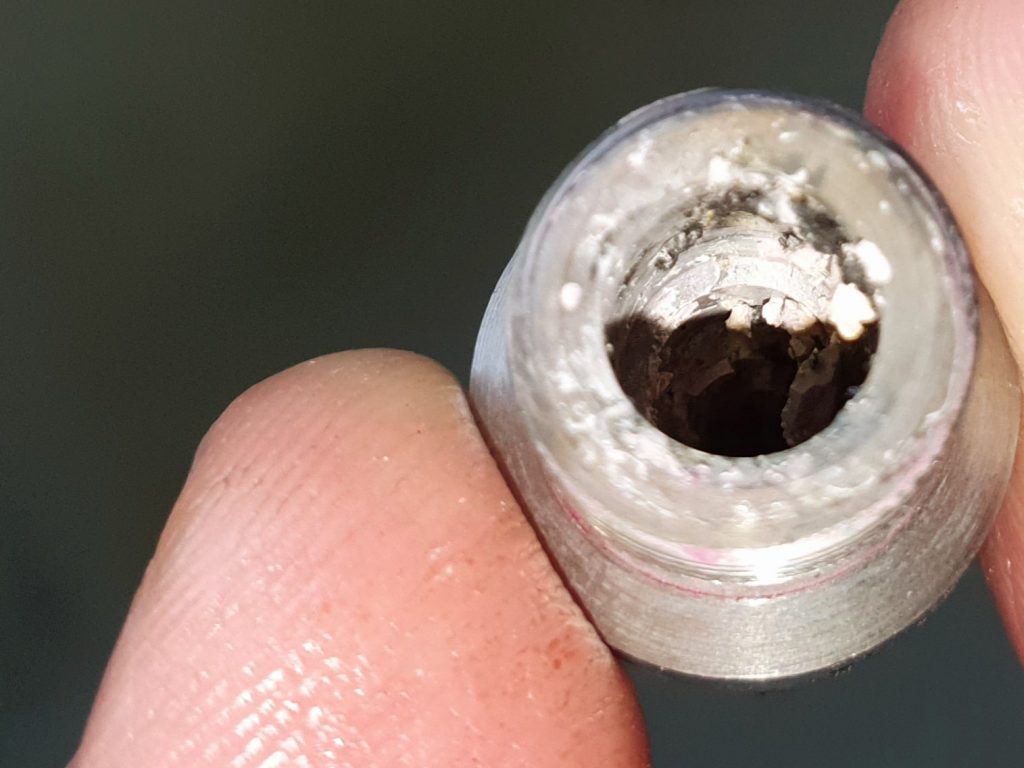

The answer is as simple as it is essential … the nozzle and the air head are the fundamental cornerstones of your spray gun.

Keep in mind that a clean or dirty air head (head) affects the final spray quality by around 60/70%.

To guarantee that each nozzle and spraycolor® production head give the best results over time, we use only selected raw materials and an established production process.

The great precision and repeatability of CNC machines allow to obtain a constant flow rate (ml/min) and a resistance to wear throughout the life of the component.

- To get the most out of your paint gun, you must first make sure that the size of the nozzle and the desired spray pattern are correct.

If you aim either of these two factors in the wrong direction you will have a strong negative impact on the workmanship and the paint will likely accumulate or be sprayed unevenly.

- First look at the chemical you will be spraying.

Heavier coatings such as resins or polyurethane-based products will require a larger gun nozzle size.

Lighter ones such as fixatives and anilines will favour smaller diameter nozzles.

For example, primers to create thick bases will be sprayed with a diameter starting from 1.2 – 1.5 mm up to 1.7 mm to allow the smooth application of the product.

On the contrary, low viscosity chemicals can be sprayed with diameters between 0.8 and 1.0 mm.

The most accurate choice between one diameter and the other will depend on the amount of product we need to spray.

Low quantities such as 80-150 ml/min can be painted with a diameter of 0.8 mm while if you were to want 150-200 ml/min the 1.0 mm diameter would be the better choice.

How to keep the “heart” of the paint gun clean?

- Air head: we recommend removing the head from the spray gun and immerse it in a detergent solution, possibly hot and NOT ACID at the end of each work cycle.

It is a simple operation and possible when the operator stops the system in the evening.

Any type of detergent is sufficient since the spraycolor® air caps are surface treated to endure and last over time.

- Before resuming the production cycle, blow the air head with compressed air for about 10/20 seconds and reassemble it on your spray gun.

! WARNING !

Nozzle: prolonged machine downtime during the painting phase can often cause blockages resulting from the sedimentation or solidification of chemical product inside the tube of the system and gun nozzle.

We therefore recommend that you finish each painting cycle (even if of short duration) by washing the circuit, possibly with water at a minimum of 30° C.